CNC3020T: EMC2 configuration and hidden features

Tags:CNC3020T only comes with a configuration for Mach3, a Windows CNC controller software I’m not really interested in. Additionally, for some weird reason, its control block requires you to adjust spindle speed manually with a potentiometer.

Fortunately, all of that can be fixed; moreover, the control block is much more powerful than it seems.

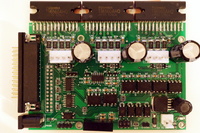

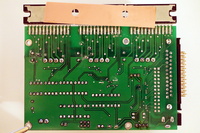

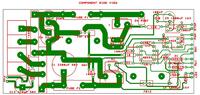

The stepper board looks like this:

The connectors J7, J8, J9 correspond to axes X, Y, Z in that order.

IC part numbers and their functions:

| Component | Part # | Function |

|---|---|---|

| U5 | AP1501 | buck converter |

| U6-U8 | TB6560AHQ | stepping motor driver |

| U10, U11, U13 | 74HC140 | hex inverting Schmitt trigger |

| U16-U21 | 6N137 | optocoupler |

| U25, U29-U32 | EL817 | optocoupler |

| black box below | B0505LS | isolating DC-DC converter |

As it can be seen, the board features quite a bit of unused functionality—it has unpopulated connectors for limit switches and spindle PWM, direction and cooling pump control. (I’ve soldered pinheads to them already.)

I didn’t trace the board completely, but it is built out of identical blocks.

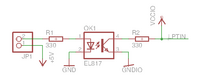

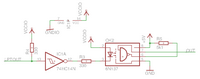

I’ve drawn its input and output circuits (GNDIO and VCCIO are provided by the

isolating DC-DC converter):

I’ve also mapped board functions to LPT pins:

| Pin # | Direction | Function |

|---|---|---|

| 2 | OUT | X Step |

| 3 | OUT | X Direction |

| 4 | OUT | Y Step |

| 5 | OUT | Y Direction |

| 6 | OUT | Z Step |

| 7 | OUT | Z Direction |

| 8 | OUT | Coolant Pump |

| 9 | OUT | Spindle Direction |

| 10 | IN | Z Limit |

| 11 | IN | Y Limit |

| 12 | IN | X Limit |

| 13 | IN | ESTOP |

| 15 | IN | Probe |

| 17 | OUT | Spindle PWM |

(“Coolant Pump” is marked on board as CP+/CP−, “Spindle Direction”

is DIR+/DIR−.)

Miscellaneous machine parameters, gleaned from the attached “documentation” (a set of Mach3 screenshots in very poor resolution black&white):

| Parameter | Value |

|---|---|

| Step Time/Space | 3000 ns |

| Direction Setup/Hold | 1000 ns |

| Steps per revolution | 400 |

| Driver microstepping | 2 |

| Leadscrew pitch | 2 mm/rev |

| Max. velocity X/Y | 33.3 mm/s |

| Max. acceleration X/Y | 200 mm/s² |

| Max. velocity Z | 11.7 mm/s |

| Max. acceleration Z | 100 mm/s² |

| Table travel X | 0..200 mm |

| Table travel Y | 0..300 mm |

| Table travel Z | −50..0mm |

All these parameters can be found in 3020T.stepconf, the source file for EMC2’s configuration wizard.

Now the funny thing is, the stepper control board has a PWM output, and the spindle control board has a PWM input:

Pin 1 (rectangular) is positive, pin 2 is negative.

It would seem that obtaining software spindle speed control is as simple

as switching the SW1 switch to position 2 (jumper adjacent to PWM)

and connecting the boards with a pair of wires. And it totally works!

I have no idea why didn’t they provide it out of the box.