CNC3020T: fixing power supply

Tags:CNC3020T is a Chinese CNC mill/router with working area of 300x200x50mm. I’ve bought one, intending to use it for PCB prototyping.

CNC machine itself is nicely built and has a strong frame. Its control box / power supply, however, is not. After about a hour of work it emitted a loud crackling noise and shorted the mains. Oops!

(By the way: the “free worldwide delivery” on eBay means that $300+ EMS charge for hauling a 26kg beast around is included in the price of the machine. This also means that the actual cost is around $250.)

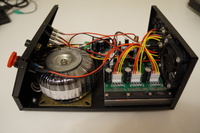

Cracking it open:

Evidently, the manufacturer was too cheap to include a switch-mode power supply! Instead, they used this enormous custom-wound transformer:

This bit me quite hard also because I blindly assumed the machine would use an SMPS and didn’t double-check that they ship me the 220V version. As you can see, it’s also 110V-only, and the autotransformer I had to buy is now useless as well.

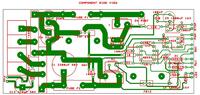

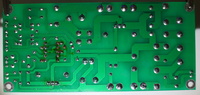

Fortunately, some kind soul from cnczone has traced the spindle control board:

Diagnostics revealed that the transformer did not have a short between primary and secondary coils,

but the 18V secondary coil nevertheless produced much higher voltage than it was supposed to.

This kills the circuit This resulted in destruction of the L7812, NE555, F2 and,

somehow, the 10kOhm potentiometer connected to Rp1.

Anyway, this isn’t hard to fix. What’s harder is to replace the transformer. One could notice that the machine is built to consume two supply voltages: 48VDC and 24VDC, rectified from 36VAC and 18VAC correspondingly. It’s also possible to deduce peak current from motor rating:

| Consumers | Voltage | Current | Power |

|---|---|---|---|

| 3x NEMA steppers (2A), NE555, level shifters, fan, etc. | 24VDC | 2A | 48W |

| Spindle motor (200W) | 48VDC | 4.2A | 200W |

Now, you may wonder why I’ve specified 2A for 24V supply despite the fact that there are three steppers and each is rated at 2A. It is simple; I’ve measured the current all three steppers consume while being driven at maximal possible speed and it’s just short of 2A.

Anyway, I ordered a 24V and a 48V switch-mode supplies on eBay. While it arrives, I’m using a temporary hack: I use my adjustable power supply to drive both inputs at 3A@29V:

You may wonder again: this doesn’t match either of the voltages this machine needs. Wouldn’t that damage it? The answer is no:

- The stepper board has a bunch of logic powered via AP1501 buck converter rated up to 40V.

- The stepper board also has TB6560AHQ, rated up to 40V as well.

- The spindle board logic is connected via L7812, rated up to 35V.

- The fan is connected directly to 24V input, but it doesn’t seem to mind.

The result is remarkably nice. At 29V, the machine consumes less than 3A (which is the limit for my power supply) with all three steppers spinning at once and the spindle at maximal speed. So it is a pretty convenient workaround.