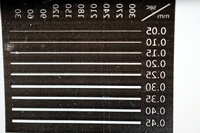

Negative photoresist calibration mask

Tags:It is convenient to quickly determine exposure time and highest resolution for a new combination of photoresist and UV light source. I’ve drawn a calibration mask just for that purpose.

The mask size is 32mm×25mm, and the SVG is made with the expectation that it will be printed on A4 paper. It is also mirrored, because the mask should be placed with toner side adjacent to PCB.

The smallest feature present on the mask, 0.5mm, is derived from the most common resolution of consumer-grade laser printers, 600dpi, which maps to dot size of 0.41mm. I would not expect such a tiny feature to be properly printed, though.

To use the mask, one should cover more and more of its surface with an opaque object from the right side (starting at “30” mark), with 30-second intervals. I turn off the UV light source when re-covering the mask to ensure that intervals stay as close to perfect time as possible.

Here’s how my printer, Brother DCP-7010R, reproduces the mask when printing at 600 dpi. The second picture is taken after applying Density Toner:

As it is seen, even the smallest 0.05mm feature is reproduced very well. A defect can be seen on the right. I suspect the cause of defect is dirty drum on my (used) printer. I have cleaned the drum in the past to get rid of similar defects, but, apparently, not thoroughly enough.

Additionally, the toner distribution becomes much more uniform after applying Density Toner. I have applied a tiny amount of the aerosol—two small splashes once just to cover the entire mask area. If the aerosol drips from the film, its quantity is excessive.