CNC3020T: simple wooden fixture

Tags:The CNC3020T CNC mill doesn’t come with anything particularly useful for fixing the workpiece to the table. In this note I describe a simple wooden fixture that is suitable for securely attaching rectangular pieces of material to the table.

Tools

- drill press

- PRACTYL 500W with 16mm collet

- d={5,6}mm drill bit for wood

- generic

- jig saw

- DEXTER IC400JS

- wood jig saw blade for clean cuts

- Bosch T301CD

Materials

- 20x40x2000 pine wood bar

- generic

- M6 nut ×2

- generic

- M6x90 bolt ×2

- generic

- M6 washer ×4

- generic

- M5 wing nut ×4

- generic

- M5x40 bolt ×4

- generic

Overview

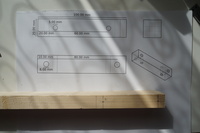

The fixture consists of two wooden parts held together with M6 bolts and clamping the workpiece, each of which is pressed to the table with M5 bolts.

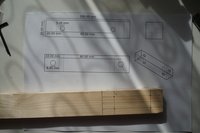

Fabrication

Mark the holes and sawing lines. Drill the holes before sawing–this helps to keep the mating surfaces perfectly parallel. Saw the fixture parts; if using a jig saw, a blade specifically designed for clean cuts helps a lot.

Note that the mating surfaces are supposed to be the outer ones, as they are much flatter than the ones produced by hand-sawing.

Conclusions

- Pine wood yields and especially fractures easily. It is imperative to use washers. Not the best material to use for this.

- With wood, it makes sense to use a drill 0.5-1mm wider than the M-rating of the fastener.

- The CNC3020T table is designed for M6 bolts; sliding the proper bolts into the table would make screwing the nut much easier. However, I wasn’t able to find the bolts of proper length and M6 wing nuts.